Product added to cart

SKU

MO-6800S-Series-MO-6816SDE630HDD10K

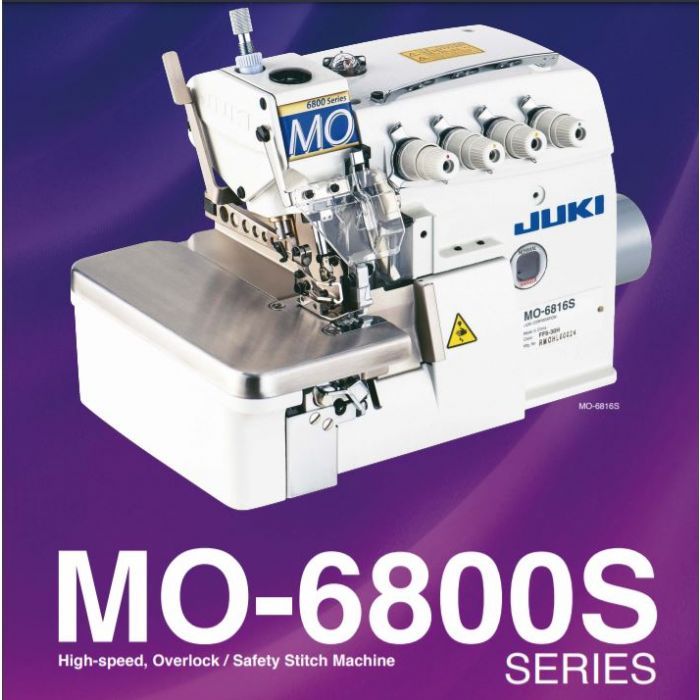

JUKI MO-6816SDE630HDD10K INDUSTRIAL SAFETY STITCH & OVER LOCK MACHINE

₹55,000.00

- The maximum sewing speed of the machine is 7000 stitches per minute

- The dry-head technology adopted by JUKI eliminates oil stain on finished material, reducing the frequency of stain removal and resewing

- Product includes stand, table and motor

Manufacturer Warranty

12 Month manufacturer warranty

Free Service

12 Month Free Service from Invoice Date

Distributor Warranty

3 MONTHS

- The needle bar mechanism and upper loop mechanism have been improved to require no lubrication

- The grease feeding mechanism and the special surface treatment given to the main drive unit both contribute to increased durability

- After lengthy periods of operation, the machine does not spray oil

- The sewing machine now has oil filler openings in two locations, one on the top looper component and the other on the sewing machine frame, which improves maintainability

Model name | MO-6816D |

Stitch type | Safety stitching |

Stitch style in the U.S.A. | 516 |

Max. sewing speed | 7,000stitches per minute |

Stitch lengthpe | 0.6~3.8(4.5)mm |

Needle gauge (mm) | 3.0, 5.0mm |

Overedging width (mm) | 4.0mm 4.0 |

Bottom differential feed ratio | Gathering 1:2 (Max. 1:4), Stretching 1:0.7 (Max. 1:0.6) |

Needle bar stroke | 24.5mm |

Inclination angle of the needle | 20° |

Needle mechanism | Lower bushing method |

Needle | DC×27 (excluding some subclass model) |

Max. lift of the presser foot | 7mm (excluding some subclass model) |

Max. presser foot pressure | 63.7N (6.5kgf) |

Stitch adjusting method | By push-button |

Differential-feed adjusting method | By lever (with micro-adjustment) |

Weight of the machine head | 27kg |

Lubrication | Automatic (The needle bar mechanism and upper looper mechanism do not require lubrication.) |

Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) |

Needle cooler | Provided as standard |

Needle thread heat remover | Provided as standard |

Micro-lifter | Option |